Code SPN 1548 FMI 5 indicates a fault with the diesel particulate filter pressure sensor. This fault is likely causing issues with the exhaust system.

When it comes to maintaining your vehicle’s health, it’s important to address any fault codes promptly. Ignoring this issue can lead to decreased engine performance and potential damage to the exhaust system. Understanding the potential consequences of this fault can help you take proactive measures to address it.

We will delve into the specifics of Code SPN 1548 FMI 5, including its possible causes and the steps you can take to resolve it. By gaining insight into this fault code, you can ensure the optimal functioning of your vehicle and prevent further complications down the road.

Credit: m.youtube.com

Understanding Code Spn 1548 Fmi 5

Understanding Code SPN 1548 FMI 5 is crucial for efficiently diagnosing and resolving issues related to this specific fault code. This code is often encountered in the context of heavy-duty vehicles and industrial equipment, and having a clear understanding of its definition, causes, and symptoms is essential for effective troubleshooting.

Definition And Explanation Of Code Spn 1548 Fmi 5

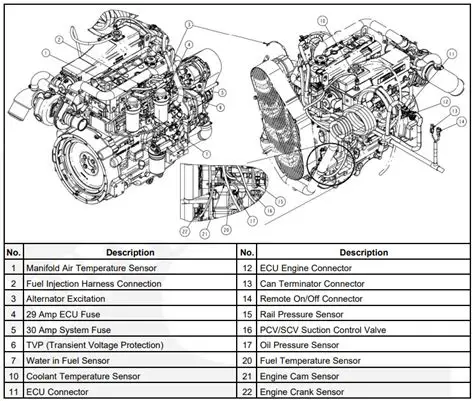

Code SPN 1548 FMI 5 refers to a specific fault code within the SAE J1939 standard used in heavy-duty vehicles and industrial equipment. This code typically indicates an issue with the engine’s fuel rail pressure sensor circuit. The FMI 5 designation points to a component’s electrical fault, indicating that the issue is related to the sensor’s electrical circuitry.

Causes And Symptoms

When encountering Code SPN 1548 FMI 5, there are several potential causes and symptoms to be aware of:

- Faulty fuel rail pressure sensor

- Wiring harness issues or electrical connections

- Corrosion or damage to sensor connectors

- Engine performance issues, such as loss of power or rough idle

- Abnormal fuel pressure readings

These causes and symptoms should be carefully evaluated to pinpoint and address the specific issue triggering the SPN 1548 FMI 5 fault code.

Credit: bremerhaven-city-ferienwohnung.de

Common Troubleshooting Tactics

When your vehicle’s diagnostic trouble code (DTC) reads Code Spn 1548 Fmi 5, troubleshooting becomes essential to identify and resolve the underlying issues. Common troubleshooting tactics involve diligent use of diagnostic tools and equipment, thorough inspection and visual checks, as well as rigorous testing of electrical components.

Diagnostic Tools And Equipment

Utilizing the right diagnostic tools and equipment is crucial in effectively diagnosing and resolving Code Spn 1548 Fmi 5. The following tools and equipment are typically used:

- Diagnostic scanner or code reader

- Multimeter

- Oscilloscope

- Inspection camera

Inspection And Visual Checks

Conducting thorough inspection and visual checks helps in identifying any visible signs of damage or wear that may be contributing to the DTC. The following visual checks are vital:

- Inspecting wiring harnesses for signs of fraying or damage

- Examining connectors for corrosion or loose connections

- Checking for damaged components such as sensors or actuators

Testing Electrical Components

Testing various electrical components is essential to pinpoint any malfunctioning parts contributing to Code Spn 1548 Fmi 5. The following components often require testing:

- Testing sensors for proper resistance and voltage readings

- Verifying proper operation of actuators and solenoids

- Inspecting circuit continuity and voltage supply

Best Practices For Efficient Troubleshooting

When it comes to efficiently troubleshooting Code Spn 1548 Fmi 5, following best practices can save you time and effort. By organizing the troubleshooting process, prioritizing steps, and documenting findings, you can streamline the entire process and identify the root cause of the issue.

Organizing Troubleshooting Process

An organized troubleshooting process can make a huge difference in resolving issues quickly and effectively. Here are some key steps to consider:

- Start with gathering all relevant information about the error code, including its definition and common causes. This will help you understand the problem better.

- Inspect the affected system or component thoroughly. Take note of any visible indications or abnormalities that might provide clues about the issue.

- Utilize diagnostic tools or software to perform tests and gather more data. This data can be invaluable in pinpointing the exact cause of the problem.

- Break down the troubleshooting process into smaller, manageable tasks. This will make it easier to track progress and ensure that no steps are overlooked.

- Collaborate with team members or experts if needed. Sometimes, a fresh perspective can uncover solutions that may have been missed.

Prioritizing Steps

When faced with a complex issue like Code Spn 1548 Fmi 5, it’s essential to prioritize your troubleshooting steps. Here’s how you can go about it:

- Start by identifying the potential causes with the highest likelihood. Focus on the most common reasons for the error code and address them first.

- Consider the impact of each potential cause on the overall system functionality. Give priority to those causes that have the highest potential to disrupt operations or cause safety concerns.

- Follow a logical sequence of steps based on the system’s architecture or dependencies. By addressing the issues in a systematic order, you can eliminate possibilities efficiently.

- Reevaluate your priorities as you progress through the troubleshooting process. New information or findings may require adjusting your approach to focus on more probable causes.

- Stay flexible and open-minded. Don’t be afraid to revisit earlier steps or go back to previous stages if new insights or evidence arise.

Documenting Findings

Proper documentation is essential for effective troubleshooting and future reference. Here are some guidelines to help you document your findings:

- Take detailed notes of all the steps you’ve taken, including test results, observations, and actions you’ve performed. This will help you avoid repeating previous steps and provide a clear record of your progress.

- Include timestamps and any relevant context in your documentation. This will help establish a timeline of events, which can be crucial during analysis and review.

- Use diagrams, tables, or visual aids where appropriate to enhance your documentation. This can make it easier to understand and communicate complex information.

- Highlight any successful troubleshooting steps or solutions that resolved the issue. This will enable others to learn from your experience and potentially replicate the same success in the future.

- Store your documentation in a centralized location accessible to the entire team. This promotes knowledge sharing and collaboration across the organization.

Advanced Troubleshooting Techniques

Interpreting Diagnostic Trouble Codes

Understanding Code Spn 1548 Fmi 5 involves decoding diagnostic trouble codes to identify the root cause swiftly.

Analyzing Data And Log Files

Efficiently analyze accumulated data through log files to pinpoint irregularities or patterns.

Consulting Service Manuals

Refer to comprehensive service manuals for detailed information on troubleshooting and troubleshooting strategies.

Case Studies

Exploring real-life examples and successful resolution strategies related to Code SPN 1548 FMI 5 can provide valuable insights into troubleshooting processes.

Real-life Examples Of Troubleshooting Code Spn 1548 Fmi 5

Case Study 1: A construction company experienced Code SPN 1548 FMI 5 on multiple vehicles, causing unexpected shutdowns during work hours.

- Driver reported issue

- Technician conducted diagnostics

- Identified faulty sensor

Successful Resolution Strategies

Case Study 2: A transportation fleet faced recurrent Code SPN 1548 FMI 5 errors, affecting daily operations and fuel efficiency.

- Upgraded software

- Replaced damaged wiring

- Conducted thorough testing

Credit: kovacsantalsommelier.eu

Preventive Maintenance Practices

Preventive maintenance plays a crucial role in ensuring the longevity and optimal performance of your equipment. By implementing regular inspections and maintenance, you can catch potential issues early on and prevent them from evolving into more serious problems. Addressing these issues in their early stages not only helps avoid costly repairs but also minimizes downtime and maximizes productivity. In this blog post, we will explore the importance of regular inspections and maintenance as well as the benefits of addressing potential issues early.

Regular Inspections And Maintenance

One of the key components of a comprehensive preventive maintenance program is conducting regular inspections and maintenance tasks. Each inspection allows you to identify any signs of wear and tear or potential issues that could impact the performance of your equipment. By taking the time to inspect your equipment thoroughly, you can detect small problems before they escalate into major disruptions.

During the inspection process, it’s essential to follow a checklist that covers all critical components of your equipment. This could include checking fluid levels, inspecting belts and hoses, examining electrical connections, and evaluating safety features. By adhering to a checklist, you can ensure that nothing is overlooked and that your equipment remains in optimal working condition.

To maintain the effectiveness of your preventive maintenance program, it’s crucial to establish a regular schedule for inspections and maintenance tasks. This may involve weekly, monthly, or yearly inspections, depending on the nature of your equipment and its usage. By following a consistent schedule, you can stay proactive in identifying and addressing potential issues, avoiding unexpected breakdowns and delays.

Addressing Potential Issues Early

In addition to regular inspections, addressing potential issues early is another preventive maintenance practice that can save you time, money, and stress. When a problem is detected during an inspection, it’s crucial to take immediate action to rectify the issue before it worsens.

By promptly addressing potential issues, you can prevent further damage to your equipment and avoid costly repairs. Fixing a minor problem at an early stage can be much more cost-effective than waiting until it becomes a major issue that affects multiple components.

Furthermore, addressing potential issues early helps minimize downtime. Unexpected equipment failures can lead to unplanned interruptions in your operations, causing delays in production and ultimately impacting your bottom line. By taking preventive action, you can proactively manage and mitigate the risks associated with equipment breakdowns.

In conclusion, regular inspections and prompt action regarding potential issues are vital preventive maintenance practices. By conducting thorough inspections and addressing problems early on, you can ensure the dependability and longevity of your equipment, minimize repairs, and optimize productivity. Implementing these preventive maintenance practices will help you save time, money, and resources in the long run, enabling your business to operate smoothly and efficiently.

Frequently Asked Questions On Code Spn 1548 Fmi 5

What Does Code Spn 1548 Fmi 5 Indicate?

Code Spn 1548 Fmi 5 usually points to a specific engine issue related to fuel pressure. It signals a potential problem with fuel delivery, requiring immediate attention to prevent performance issues.

How Can I Diagnose Code Spn 1548 Fmi 5?

Diagnosing Code Spn 1548 Fmi 5 involves checking fuel pressure levels and inspecting fuel delivery components. A diagnostic scan tool can help identify the exact cause, enabling timely troubleshooting and repair to rectify the issue.

Why Is It Crucial To Address Code Spn 1548 Fmi 5 Promptly?

Addressing Code Spn 1548 Fmi 5 promptly is vital to prevent further engine damage and avoid potential breakdowns. Ignoring this code can lead to decreased performance, increased fuel consumption, and potentially expensive repairs in the future.

Conclusion

To sum up, understanding and addressing the Code Spn 1548 Fmi 5 is crucial for maintaining optimal performance in your vehicle. By identifying the root cause and taking appropriate action, you can prevent further damage and ensure the safety of both yourself and your vehicle.

Regular check-ups, timely maintenance, and seeking professional assistance when needed are the keys to keeping your engine running smoothly. Stay proactive and informed in order to minimize potential complications and maximize the efficiency of your vehicle.