The Cummins ISC 8.3 belt routing diagram can be found in the engine manual. To locate it, refer to the specific section on belt routing.

Cummins ISC 8. 3 engines play a critical role in powering various heavy-duty vehicles and equipment. Proper maintenance of the engine’s belts is essential for ensuring optimal performance and longevity. Understanding the correct belt routing is crucial for efficient operation and avoiding potential issues like slippage or wear.

By referring to the engine manual, operators and technicians can easily identify the correct path for the belts to follow. In this guide, we will explore the importance of belt routing for Cummins ISC 8. 3 engines and provide tips for ensuring proper installation and maintenance.

Credit: m.made-in-china.com

- 2. Understanding The Cummins Isc 8.3 Engine

- 3. Importance Of Proper Belt Routing

- 4. Identifying The Belt Routing Diagram

- 5. Steps To Follow For Belt Replacement

- 6. Common Issues And Troubleshooting Tips

- 7. Regular Maintenance And Inspection

- Frequently Asked Questions For Cummins Isc 8 3 Belt Routing

- Conclusion

2. Understanding The Cummins Isc 8.3 Engine

The Cummins ISC 8.3 engine is renowned for its performance and reliability in a variety of applications. Let’s delve deeper into the specifications and common uses of this powerful engine.

2.1 Specifications

Here are some key specifications of the Cummins ISC 8.3 engine:

| Displacement: | 8.3 liters |

| Power Output: | 260-380 horsepower |

| Torque: | 900-1200 lb-ft |

| Fuel Type: | Diesel |

2.2 Common Applications

The Cummins ISC 8.3 engine is commonly used in:

- Medium-duty trucks

- Commercial buses

- Recreational vehicles (RVs)

- Emergency vehicles

Credit: www.mylittlesalesman.com

3. Importance Of Proper Belt Routing

Ensuring the correct Cummins ISC 8.3 belt routing is crucial for the performance and longevity of your engine. Proper belt routing plays a vital role in maintaining the optimal functioning of your Cummins ISC 8.3 engine.

3.1 Ensuring Optimal Performance

Optimal performance of the Cummins ISC 8.3 engine heavily depends on precise belt routing. The correct belt placement and tension are essential for ensuring that all engine components function efficiently.

3.2 Preventing Belt Failure

Incorrect belt routing can lead to premature wear and failure of the belt. By ensuring proper belt routing, you can extend the lifespan of the belt and prevent unexpected breakdowns in operation.

4. Identifying The Belt Routing Diagram

The belt routing diagram is an essential tool for maintaining the proper functionality of your Cummins ISC 8.3 engine. It helps in correctly positioning the belts that power various engine components, such as the alternator, water pump, and air conditioning compressor. By following the belt routing diagram, you can ensure smooth and efficient operation of your engine. In this section, we will discuss how to locate the diagram and understand its components.

4.1 Locating The Diagram

The belt routing diagram for the Cummins ISC 8.3 engine can typically be found under the hood of your vehicle. It might be displayed on a sticker or decal attached to the engine compartment or the radiator shroud. This diagram is usually labeled with the specific engine model and shows the correct path for each belt, including the tensioner and idler pulleys. It’s important to locate the diagram before starting any belt replacement or maintenance tasks.

4.2 Understanding The Components

Before diving into the belt routing diagram, it’s crucial to familiarize yourself with the various components it references. Understanding the components will help you accurately follow the diagram for proper belt installation. Here are the key components you will encounter:

| Component | Description |

|---|---|

| Tensioner Pulley | This pulley maintains the correct tension on the belt, preventing slippage and ensuring optimal power transfer. |

| Idler Pulley | The idler pulley guides the belt along its path and helps maintain tension, ensuring it stays in place. |

| Alternator | The alternator is responsible for generating electrical power to recharge the battery and supply power to various electrical systems. |

| Water Pump | The water pump circulates coolant throughout the engine, helping to maintain proper operating temperature. |

| Air Conditioning Compressor | The compressor is an integral part of the vehicle’s HVAC system, providing cool air in warm weather. |

By understanding the role of each component, you can better interpret the belt routing diagram and ensure that each belt is correctly routed around them.

5. Steps To Follow For Belt Replacement

When it comes to maintaining your Cummins ISC 8.3 engine, belt replacement is a crucial aspect of routine maintenance. Following the correct steps for belt replacement ensures optimal engine performance and longevity. Here are the 5 key steps to follow for belt replacement:

5.1 Gathering The Necessary Tools

Before starting the belt replacement process, gather the necessary tools for the job. These may include a ratchet and socket set, belt tension gauge, and any specific tools required for your particular engine model. Having all the tools on hand will streamline the process and help ensure a successful belt replacement.

5.2 Removing The Old Belt

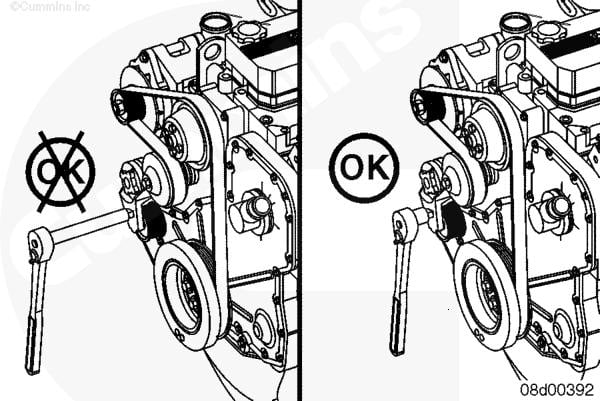

The first step in replacing the belt is to remove the old belt from the engine. Start by locating the belt tensioner and using the appropriate tool to release the tension on the belt. Once the tension is released, carefully remove the old belt from the pulleys, making note of its routing for reference when installing the new belt.

5.3 Installing The New Belt

With the old belt removed, it’s time to install the new belt. Begin by following the routing diagram for your specific engine model, ensuring the new belt is positioned correctly on each pulley. Take care to avoid twisting or misaligning the belt during installation, as this can lead to premature wear and potential damage to the belt.

5.4 Adjusting Belt Tension

Once the new belt is correctly installed, the final step is to adjust the belt tension. Utilize a belt tension gauge to ensure the tension is within the manufacturer’s specified range. Proper belt tension is critical for the smooth operation of the engine accessories and helps prevent premature wear on the belt and pulleys.

6. Common Issues And Troubleshooting Tips

6. Common Issues and Troubleshooting Tips

6.1 Belt Misalignment

One of the common issues with Cummins ISC 8.3 belt routing is belt misalignment. This can occur due to improper installation or worn-out pulleys. To troubleshoot this problem, visually inspect the alignment of the belts. Use a straightedge to check if the belts are running parallel to the pulleys. If misalignment is detected, adjust the tension and realign the belts to the manufacturer’s specifications. Regular maintenance and proper installation can prevent belt misalignment issues.

6.2 Squeaking Or Chirping Noises

Squeaking or chirping noises from the Cummins ISC 8.3 belt routing system indicate potential issues with belt tension or pulley misalignment. Inspect the belts for signs of wear and proper tension. If the belts appear to be in good condition and properly tensioned, check the pulleys for any misalignment. It’s crucial to address these noises promptly to prevent further damage to the belts and pulleys. Lubricating the pulleys and ensuring proper tension can resolve squeaking or chirping noises.

6.3 Excessive Belt Wear

Excessive belt wear is a common issue that can occur with Cummins ISC 8.3 belt routing. This can be caused by factors such as misalignment, improper tension, or worn-out pulleys. To troubleshoot excessive belt wear, inspect the belts for signs of fraying, cracking, or glazing. Check the tension and alignment of the belts to ensure they meet the manufacturer’s specifications. Replace any damaged belts and address the root cause of excessive wear to prevent future issues. Regular maintenance and proper tensioning are essential in preventing excessive belt wear.

Credit: www.justanswer.com

7. Regular Maintenance And Inspection

Regular maintenance and inspection of the Cummins ISC 8. 3 engine includes checking the belt routing to ensure optimal performance and longevity. Following the manufacturer’s guidelines for belt routing is crucial to prevent wear and tear, ultimately prolonging the engine’s lifespan.

Regular inspections help detect any issues early on for timely repairs.

One of the keys to maintaining optimal performance in your Cummins ISC 8 3 engine is regular maintenance and inspection. By following a routine maintenance schedule and conducting inspections, you can ensure that your engine’s belt routing is in proper working order. In this section, we will cover three important aspects of regular maintenance and inspection: checking belt tension, cleaning and lubricating, and replacing worn pulleys. Let’s dive into each of these tasks and discover how they contribute to keeping your Cummins ISC 8 3 engine running smoothly.7.1 Checking Belt Tension

Proper belt tension is crucial to the efficient operation of your engine. If the belt is too loose, it can slip and cause reduced power output or even engine stalling. On the other hand, if the belt is too tight, excessive strain can be put on the pulleys and other components. To ensure the belt tension is just right, follow these steps:- Start by locating the tensioner pulley. This is typically marked with an arrow or a belt routing diagram.

- Using a wrench or a belt tension gauge, apply pressure to the tensioner pulley to measure the tension on the belt.

- Ensure that the belt deflects slightly when pressure is applied. If it feels too loose or too tight, adjustments may be necessary.

- Consult your engine’s manual for specific tension specifications and make any necessary adjustments accordingly.

7.2 Cleaning And Lubricating

Regular cleaning and lubrication of the belt and pulleys are essential to prevent dirt, debris, and rust from compromising their performance. Follow these steps to keep your belt routing system clean and well-lubricated:- First, visually inspect the belt and pulleys for any signs of dirt, debris, or rust. If any buildup is present, use a clean cloth or brush to remove it.

- Apply a recommended belt conditioner or lubricant to the belt, ensuring that it is evenly distributed.

- Inspect the pulleys for any signs of wear or damage. If any pulleys are worn or damaged, they should be replaced promptly.

7.3 Replacing Worn Pulleys

Over time, pulleys can wear down due to constant friction and heat. If any pulleys in your engine’s belt routing system show signs of wear or damage, it is crucial to replace them promptly. Failure to do so can result in belt misalignment, increased belt wear, and potential engine damage. When replacing worn pulleys, follow these steps:- Identify the specific pulley that needs to be replaced.

- Locate the appropriate replacement pulley according to your engine’s specifications.

- Using the proper tools, remove the old pulley and install the new one in its place.

- Ensure that the new pulley is properly aligned with the belt and other components.

- Finally, perform a visual inspection and check the belt tension to ensure everything is in working order.

Frequently Asked Questions For Cummins Isc 8 3 Belt Routing

What Is The Importance Of Belt Routing In Cummins Isc 8.3 Engines?

Belt routing in Cummins ISC 8. 3 engines is crucial for optimal performance and efficiency. It ensures proper power transmission to engine components, such as the alternator and water pump, leading to smooth operation and extended lifespan of the engine.

How Do You Determine The Correct Belt Routing For Cummins Isc 8.3 Engines?

To determine the correct belt routing for Cummins ISC 8. 3 engines, refer to the manufacturer’s manual or diagrams. Carefully follow the specified routing pattern, ensuring the belt is properly aligned with the pulleys. Additionally, double-check for any specific instructions related to tensioning and alignment adjustments.

What Are The Common Signs Of Incorrect Belt Routing In Cummins Isc 8.3 Engines?

Incorrect belt routing in Cummins ISC 8. 3 engines may manifest as squealing noises, abnormal vibration, or erratic functioning of engine accessories. Visual inspection can also reveal misalignment or unusual wear patterns on the belt. Addressing these issues promptly is essential to prevent further damage to the engine.

Conclusion

Understanding the belt routing for the Cummins ISC 8. 3 engine is crucial for its smooth operation and longevity. By ensuring the correct alignment and tension of the belts, you can prevent engine damage and reduce the risk of unexpected breakdowns.

Regular inspection and maintenance of the belt system will help keep your Cummins ISC 8. 3 engine running efficiently and reliably. Remember to consult the official documentation or seek professional assistance for accurate belt routing information.